Prowell to Increase Corrugated Sheet Production Capacities in Central Europe

(Germany, April 21, 2017) Prowell, a company belonging to Progroup AG, pursues its Two Twentyfive strategy with determination and continues expanding at a fast pace with two further corrugated sheet board plants. Europe’s fastest growing corrugated board manufacturer is thus expanding its production capacities by a further 250,000 tonnes in the medium term. As from 2018, it will have a production capacity totalling 1,380,000 tonnes of corrugated sheet boards per year. This further secures Progroup’s market leadership in the Central European corrugated sheet board market. While Prowell Plößberg (Germany) and Prowell Trzcinica (Poland) take their successful partnership to a new level with a further packaging park in Drizzona (Italy), the most powerful corrugated board plant of the entire industry is being built in the UK, close to the existing site in Ellesmere Port.

Italy: expansion into new markets — Prowell penetrates the Italian board market

With the production launch of Prowell Drizzona (Italy), which is scheduled for the first quarter 2018, Progroup shall be entering the largest corrugated sheet board market in Europe and consequently further enhancing its capacities and the associated market share as part of the Two Twentyfive strategy.

The newly founded Prowell S.r.l. will be operating a corrugated board machine in Drizzona next to the Italian packaging specialist Imbal Carton S.r.l. and supply it with corrugated board at no additional logistics expenditure. This pursues the extremely successful Packaging Park II model of Prowell Plößberg (Germany) and Prowell Trzcinica (Poland).

A 2.8-metre-wide corrugated board machine will be operated at the new site, and will produce 100,000 tons of corrugated sheet boards per year at a working speed of 350 m/min. We are planning to produce single and double-wall in the grades B, B NG, C, E and combinations. This will create approx. 40 new high-tech jobs at Prowell.

The Prowell plant is fully integrated in the Progroup network for high efficiency and centralised control of all relevant data and orders. This not only allows us to achieve maximum synergy and integration effects within the business model of Progroup but also within the framework of the packaging park model.

Great Britain: the most efficient and powerful corrugated sheet board mega plant in the world

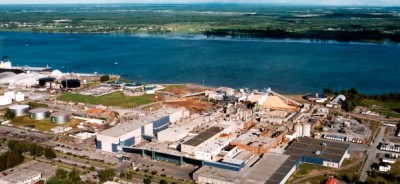

A little over eight years ago, the corrugated sheet board plant of Prowell Limited, which had just been founded in Ellesmere Port near Liverpool, launched its production on a 2.50 m wide corrugated board machine from the first Prowell plant. As part of the Two Twentyfive strategy concept, a reform strategy with a generation change of the first Prowell system is now taking place to successfully meet market growth and customer requirements for delivery reliability and quality.

The most efficient and most powerful corrugated sheet board mega plant of the entire industry will be created by the third quarter 2018, within just a few kilometres of the current location. A total of EUR 75 million is being invested in a high-tech plant, which is set to become a highly competitive production facility with efficient process flows. Following a start-up and optimisation phase, the plant will produce 235,000 tonnes of corrugated board each year with a working width of 3.35 m, thus seamlessly integrating into the Progroup mill system.

Industry 4.0 at Progroup

At Progroup, Industry 4.0 is reflected in largely self-optimizing production lines that operate automatically with as little human intervention as possible. In this context, the three-men corrugator represents the next logical development step that already started with the introduction of the one-man dry-end concept at the Prowell plant in Plößberg. In the new plant in Ellesmere Port, it leads to a whole series of technical innovations and organisational developments. True to the Progroup slogan Power of Innovation, the new location will thus become the absolute benchmark of the entire industry.

Some of the most important innovations include a 350 m/min steady stater, the improvement of the one man dry end concept introduced in the Plößberg and Trzcinica packaging parks, a highly efficient high-rack storage system, automatic pallet handling, edge protection, strapping as well as the optimisation of waste disposal and the glue system.

The additional use of a CHP (combined heat and power) system to produce electricity and heat places particular emphasis on energy efficiency and environmental protection. Excess heat from electricity generators is re-absorbed in a special process and used for refrigeration or even reapplied directly for heating purposes — green high-tech made by Progroup.

The overall concept is rounded off by a sound absorption system that, besides ensuring very low noise pollution, also caters for low temperature fluctuations. An excellent basis for a pleasant and very modern work environment. (Source: Progroup AG (progroup.ag/)