Link: Microcellulose gains foothold in paperboard

(Sweden, January 24, 2017) Stora Enso and BillerudKorsnäs announce plans to phase in microfibrillated cellulose (MFC) in paperboard products. Lightweight milk cartons with Stora Enso MFC are already market tested.

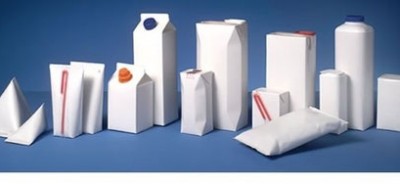

Microfibrillated cellulose (MFC) is set to transform paperboard furnish according to the intentions of two major European paperboard producers. Stora Enso and BillerudKorsnäs are making plans to phase in MFC as part of their papermaking furnish. In fact, as an early market entrant, light weight milk cartons using Stora Enso MFC are already test marketed in Eastern Europe. It’s a foothold, to start with.

Stora Enso says that 500,000 tonnes per year of its paperboard could contain MFC, which could reduce the products’ weight and save fiber furnish. That’s improved material efficiency, in other words. The company is investing a total of EUR 9.1 million (12.7 million CAD) in its consumer board mills in Imatra and Ingerois, Finland, and Fors, Sweden, to continue the commercialization of MFC and to accelerate product development. The plants are scheduled to start production by the end of 2017 and expected to reach full production within 3 to 5 years. In addition to lightweight products, the company is targeting new applications, which will include barrier layers for grease and oxygen and biodegradable film as a replacement for aluminum foil currently used in paperboard packaging. …

100 million containers test marketed

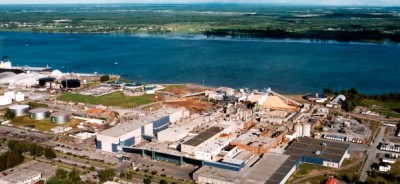

Stora Enso has operated a pre-production MFC plant at its Imatra, Finland mill since 2011. The company has focused initially on the liquid packaging board segment, being the first company to have successfully launched a commercial paperboard packaging including MFC. Since 2015, MFC has been used for source reduction and to improve board quality in dairy product packaging through its partner Elopak, a liquid food container manufacturer based in Norway.

Elopak’s lighter weight Pure-Pak® milk cartons are constructed with Stora Enso’s liquid packaging board containing MFC. The cartons have been test marketed in Eastern Europe. Source: Stora Enso website and Elopak

In a quote from the Stora Enso website, Tom Egenes, Director of Strategic Sourcing at Elopak, says, “By using MFC, we get the maximum yield out of the raw material and thus more packaging material per ton of board. Important properties, such as stiffness and internal strength, are maintained, with less weight. Within Europe, there are various incentives and regulations to reduce the weight of packaging material. The partnership with Stora Enso makes it easier for us to reach these targets.” Elopak has piloted the lightweight containers in the Eastern European market, offering it to all dairies in the region. More than 100 million packages have been produced successfully.

To read complete report Go To: Microcellulose gains foothold in paperboard (Source: paperadvance.com)

Cover Image: A pre-production MFC plant is located at Stora Enso’s Imatra mill complex in Finland (courtesy Stora Enso)