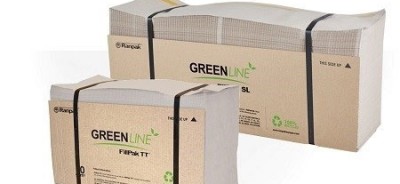

Smurfit Kappa Collaborates with Sun Chemical on Laser-based Marking for Packaging

(Dublin, Ireland, Feb. 27, 2017) Smurfit Kappa has collaborated with Sun Chemical to deliver digital laser-based coding that supports customer packaging and labeling requirements.

The new coding solution for secondary cartons combines Smurfit Kappa’s flexo printed corrugated boxes with Sun Chemical’s SunLase activated coating system resulting in high quality, reliable, late stage coding, which allows customers to laser mark packaging at the end of manufacturing operations. With the capacity to laser mark at the typical speed of an automated packing line, it offers a replacement for direct thermal labelling.

As a result, there is less disturbance during the packaging line as there is no requirement for labelling and printing, according to Smurfit Kappa. “This saves the business time and ultimately, drives operational efficiencies. The SunLase system is clean, hygienic (no inks or chemicals are used in the production) and is a much more reliable form of coding, when compared with labels and printing. SunLase is available in white and transparent laser-sensitive ink,” the company said in a press release.

Extensively tested within the FMCG (fast-moving consumer goods) sector, the late stage solution is being successfully used on packaging for leading companies.

Michel Vanhems, SunInspire, Special Effects Inks, Functional Coatings and SunLase Product Manager EMEA at Sun Chemical, said, “As regulations for traceability continue to grow, combined with the need for delivering fast, efficient and cost effective output, our partnership with Smurfit Kappa has enabled us to combine our expertise to deliver a digital laser-based solution that meets all the demands of industrial applications.” (Source: Smurfit Kappa)