Research efforts to ensure more energy-efficient papermaking

(Stockholm, Sweden, 31 October 2016) The Swedish Energy Agency has recently awarded a grant of MSEK 11 to develop and demonstrate new dewatering processes for papermaking that can eventually be scaled up. Innventia is coordinating the three-year project that is now gathering momentum.

Hannes Vomhoff, Eva Ålander, Maria Sedin and Mattias Drotz at Innventia all have important roles in the project.

The project aims to develop and demonstrate new, more energy-efficient process solutions on a pilot scale, which it is thought could be implemented industrially within five years. In the case of tissue production and papermaking, energy consumption during the drying stage accounts for a significant portion of total energy needs. Thus, there is immense scope for energy efficiency if dewatering processes, such as wet pressing, and drying can be improved. In the case of thickening, the focus is on using centrifugation. Improved dewatering and drying is expected to be achieved by operating at a significantly higher dewatering temperature, and using a combination of IR-drying, steel belts and conventional drying.

The project includes both fundamental laboratory studies and pilot-scale trials. Industrial case studies will then be used to quantify the energy savings, which can be used as decision-making data for a potential industrial implementation.

“Innventia has developed a number of new fibre-based reinforcing additives that have shown immense potential in terms of improving the efficiency of tissue, paper, and board production. The industrial implementation of these additives give rise to a number of challenges, mainly due to a lack of efficient dewatering processes adapted for the new additives. These additives normally have a high water content, and removing the water can be an extremely tricky process, which is why new process solutions are needed in this area,” says project manager Eva Ålander.

Five companies are participating in the project: Valmet, Sandvik, Ircon Drying Systems, Albany International and Alfa Laval. The research results are expected to have a big impact on future dewatering and drying processes used in tissue production and papermaking. The project content is based on Innventia’s work within the fields of stock design, nanocellulose, tissue, and papermaking. Much of the work will involve Innventia’s FEX pilot paper machine. (Source: Innventia)

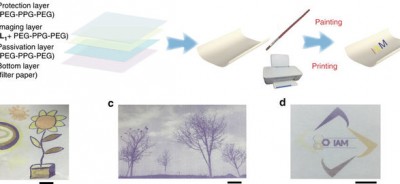

Pictured Above: The diagram details conventional paper making process (for representational purposes only / courtesy http://www.paperonline.org)