Valmet carried out the first maintenance shutdown of CMPC Guaíba’s new pulp line in Brazil

(Brazil, September 28, 2016) Valmet was given an important role in the first maintenance shutdown of CMPC Guaíba’s new pulp line in Brazil. The executed shutdown is one of the biggest shutdowns managed by Valmet. The facility’s pulp line 2, also called G2, invested in planned maintenance in order to reach its annual capacity of 1.5 million tons/year of bleached eucalyptus pulp. The maintenance shutdown was carried out by Valmet and it took place between July 31 and August 10, 2016.

“We made careful planning with the customer for several months, and thanks to this work we were able to start the line again faster than planned. The geographical location of CMPC Guaíba’s pulp mill demands special attention on safety and environmental issues as well as good cooperation with local community. In this respect, our role is not only to ensure that the equipment is running well, we also need to take care of the overall aspects which are part of the mill’s operation”, says Rogério Duarte, Valmet’s Mill Sales Manager.

“Valmet contributed to the successful shutdown of G2 with its personnel’s technical skills and organization, and its planning, safety and environmental state-of-the-art criteria. There is no doubt, Valmet and CMPC reinforced their partnership and I believe the company will be a strong candidate for future planned shutdowns,” says Fernando Pereira, Maintenance Manager at CMPC.

Working towards a common goal

Valmet’s expertise was the key for a well-planned shutdown. “We avoided rework during G2 maintenance as both Valmet and CMPC teams worked together focusing on the same goal,” says Paulo Ormeneze, Valmet’s Services Manager in South America.

Valmet was in charge of the overall maintenance of the core equipment delivered to this Southern Brazilian pulp mill including cooking, the fiber line, drying machines, causticizing, the evaporation plant and the recovery boiler. All maintenance activities were performed in line with Valmet’s and CMPC’s safety, quality and environmental criteria.

The first shutdown at CMPC Guaíba G2 was executed by Valmet’s Service and Project Execution teams. Taking into account third-party companies and suppliers, Valmet managed altogether over 600 people at the site during 10 days.

Information about the customer CMPC and Guaíba mill

CMPC Celulose Riograndense Ltda is part of the Chilean group, CMPC Celulosa, one of the largest forestry-based companies in Latin America. Its mills in Chile and Brazil produce around 4 million tonnes of pulp per year.

Guaíba pulp mill in Rio Grande do Sul state in southern Brazil has two pulp production lines. The new line G2 was delivered by Valmet and was started up in May 2015. (Source: press release)

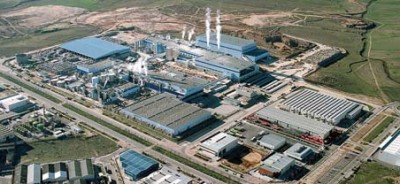

Pictured Above: CMPC Guaíba’s new pulp line in Brazil was delivered by Valmet in 2015